Reimagining Surface Infrastructure: Cost-Saving, Compliant, and Customised

- Megan Dickinson

- Aug 18, 2025

- 2 min read

Updated: Aug 18, 2025

Your existing assets hold

more potential than you think

When the team at Crown Technologies was engaged for the Bulga Project, the challenge was clear: design a surface infrastructure system that delivered results while keeping costs down. Our engineers knew the key would be to maximise the use of existing onsite infrastructure while being future-focused on integrating new technology where it would have the biggest impact.

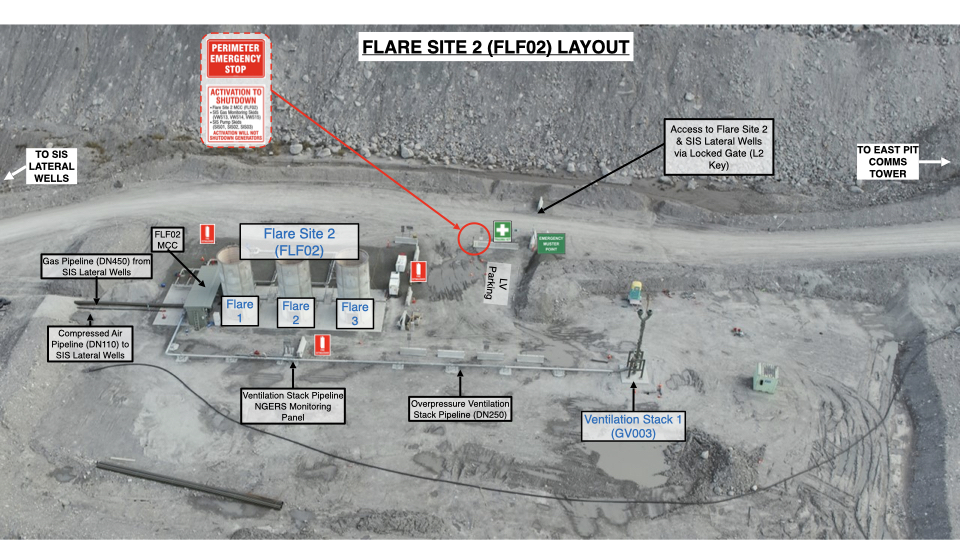

Smarter Infrastructure Design

Rather than starting from scratch, Crown Technologies carried out a full review of the site’s infrastructure. We designed pipe networks, vent stacks, and flare upgrades that leveraged what was already in place saving both time and money. Our approach also included risk assessments and safety reviews at the design stage, ensuring that every part of the system was fully compliant and reliable.

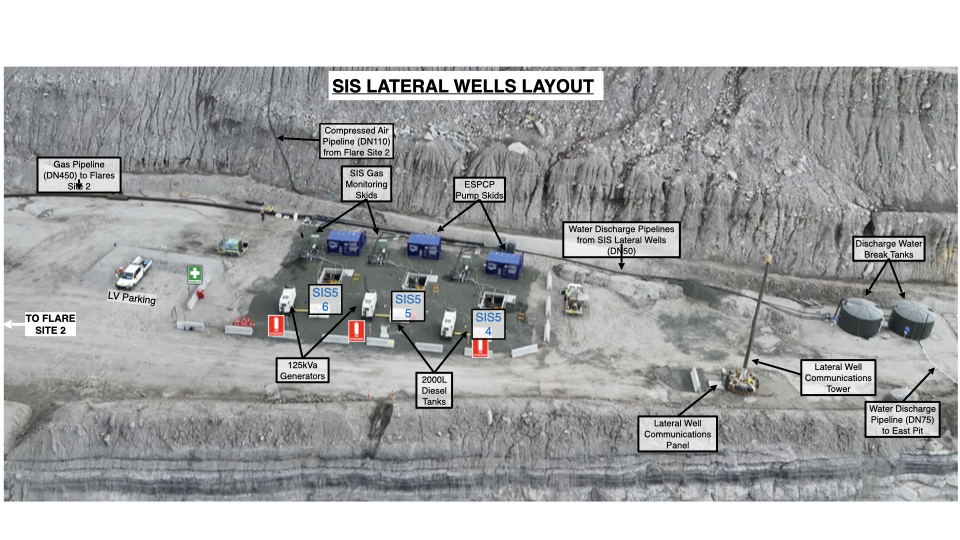

Introducing ESPCP Technology to Coal Mining

One of the standout features of this project was the use of an Electric Submersible Progressing Cavity Pump (ESPCP) system, a new concept for the coal mining industry. Unlike traditional rod-driven pumps, the ESPCP places the electric motor down the borehole, eliminating the need for mechanical surface parts. This innovation brings a host of benefits:

Lower failure rates by removing rods and surface driveheads

Improved safety and smaller footprint at the wellhead

Reduced power consumption thanks to high-efficiency motors

Reliable performance even in wells dealing with gas, sand, or wax issues

For Bulga, this meant a pumping solution that was not only efficient but also low-maintenance and built to last.

Upgrading the Flare System

The site’s existing flare was fully upgraded and commissioned by Crown Technologies to meet compliance requirements. This ensured safe management of gases, supported by a backup vent stack included in the design to provide additional risk mitigation.

Custom Modifications

Crown Tech also modified and upgraded the VWS skids to suit this specific application, ensuring seamless integration with the ESPCP and flare systems. Every element was tailored to Bulga’s operational needs.

The Result

The Bulga Project is a strong example of how Crown Technologies combines innovation with practical cost-saving strategies. By using available infrastructure, introducing ESPCP technology, and upgrading existing systems, we delivered a solution that’s efficient, compliant, and future-focused.

At Crown Technologies, we don’t just design systems: we create smarter, safer, and more sustainable solutions that help our clients get the most from their investment that are tailored to every need, project and site.

From upgrades to innovation, we make the most of what you already have.

-900px-w-72ppi.png)

Comments